In last article we told you about the new acoustic holography technology which is the basis of SVS. Now we at Arman have successfully completed a pilot project in which we demonstrated the results of this technology. But before we were invited to participate in the pilot project, we came a long way. We were looking for applications of acoustic holography technology. We put together several scenarios for using SVS.

Example of Armtel SVS (Sound Vision System)

Example of Armtel SVS (Sound Vision System)

Where can acoustic holography technology be useful?

Continuous operation is the most important requirement for equipment. Installations are running virtually non-stop, so there are stringent requirements.

Detecting and precisely locating faults at an early stage is a major challenge.

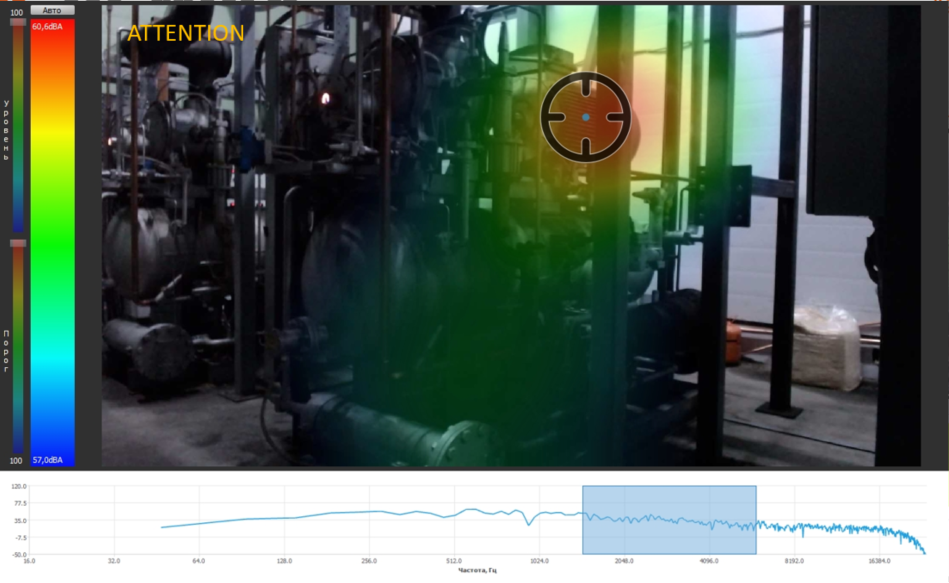

We had the task of investigating a unit at a steel mill.

Over several days we recorded the operation of the unit. We analyzed the acoustic patterns and found that there were abnormalities in the machine’s operation.

Non-contact diagnostics of equipment malfunctions

As a result of this research, my team and I were able to discover new possibilities for SVS:

Noise is a pollutant that is often underestimated. There are studies that show that at least 2 percent of all heart attack victims are related to traffic noise. At night, traffic noise can disrupt health by affecting sleep quality.

Therefore, the requirements imposed by legislators on the operation of technical devices are becoming increasingly stringent. It is not enough to know the noise level, it is necessary to localize it precisely in order to take measures to eliminate it.

Our colleagues from a large railroad company asked us to assess the impact of rail type on noise characteristics. To do this, we needed to measure the noise level when different materials were used in the construction of rails.

A sound map was built. We analyzed the acoustic footprint, and the result was that one type of rail had a lower noise level.

The study helped open up new possibilities for SVS in this area as well:

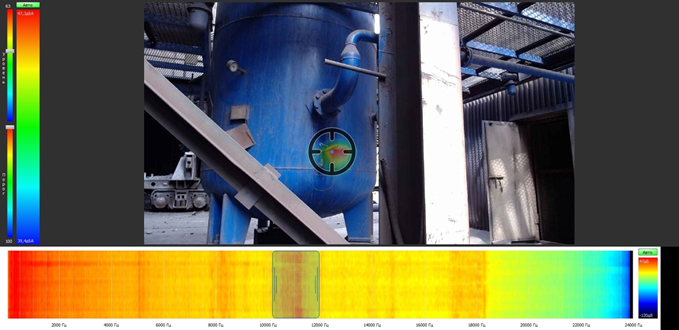

Statistics show that hundreds of pipeline accidents, both domestic and foreign, occur annually, resulting in reduced flow capacity, environmental contamination and costly, in terms of finances, repairs.

Search for tie-ins and gas leaks in pipelines

Line integrity is the most important problem of pipeline operation, which can be solved by systematic control of pipeline leaks and timely elimination of detected defects.

The main requirement for the means and methods of detecting significant leaks is fast location of the leak.

Leak location is a delicate matter. In a noisy room it’s impossible to hear a leak with your ear, but with acoustic holography technology you can. We were able to detect a suspicious sound source in one plant that we didn’t even know existed.

Search for tie-ins and gas leaks in pipelines

Such a scenario opened up new SVS capabilities for us:

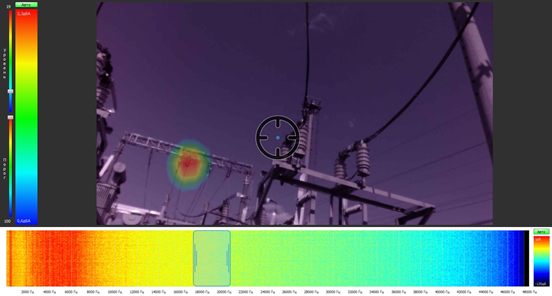

Power transmission lines are the connecting element in power systems. To reduce transmission losses over long distances and detect faults in time, it is necessary to use monitoring and diagnostic tools for electrical equipment.

Fault detection in power grids

We were tasked with detecting the location of corona discharges in a traction substation. As a result of our work on this case, we identified new SVS capabilities for detecting faults in power grids:

Corona discharge on phase B

We at Arman continue to explore new areas where acoustic holography technology can be useful.