Open Joint Stock Company TANECO, Tatarstan Oil Processing Complex, is Russia’s largest oil refining Complex.

The company was founded on 12th October 2005 and consists of three interconnected plants:

Planned production is 18 kinds of oil deep conversion products – starting from engine fuels of European Standards to feeding components for a wide range production of unclaimed petrochemical products.

CHALLENGE

Due to the hazardous conditions of industrial sites it was necessary to install PA/GA system including emergency one which made it possible to improve safety, prevent human losses and to reduce material expenditures in emergency situations.

Another main concern was improving of technology process management at the industrial site which results in higher labor productivity.

CUSTOMER’S FEEDBACK

«Thanks to the well coordinated work of Armtel specialists the intercom system was supplied and put into operation. The commissioning works were carried out quickly, efficiently and with high quality. That allowed us to prepare the launch of the plant first capacities on schedule and to provide the necessary security level at the industrial site».

I. Nugmanov CTO at OJSC TANECO

PROJECT DETAILS

TPC Orion-Kazan, OJSC / OJSC Taneco Oil Refining and Petrochemical Complex, 1st Complex

Delivery terms:

The solution:

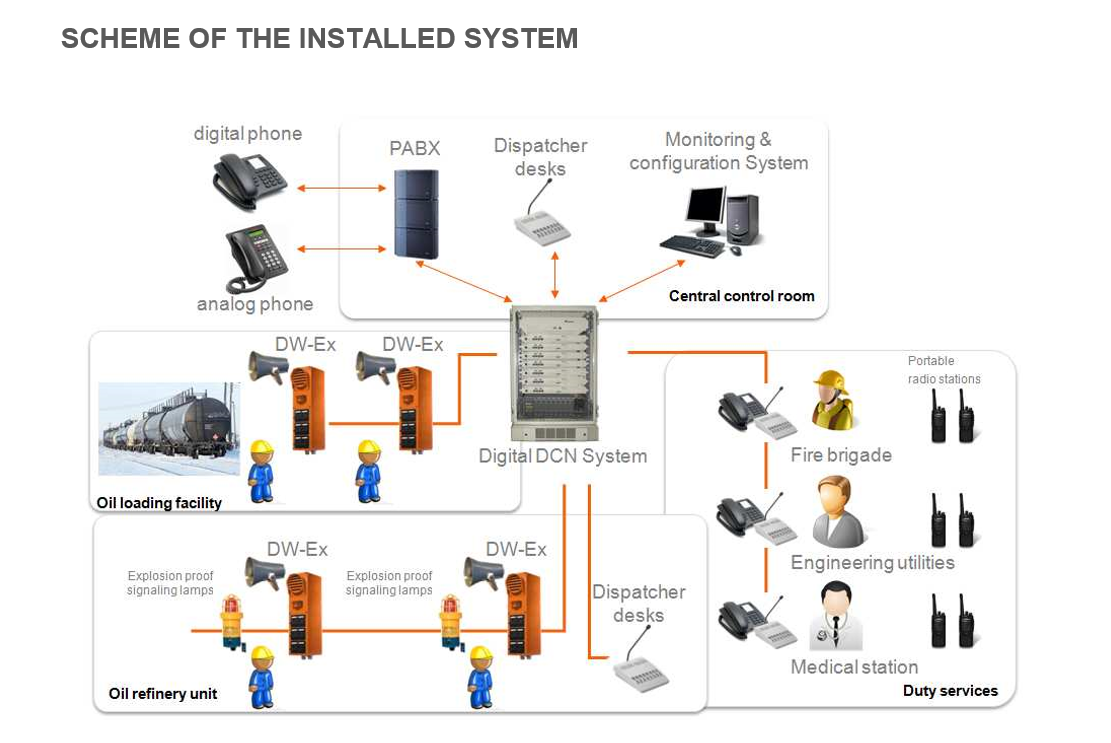

PA / GA system is based on DCN central exchange modules which are connected with subscriber devices. The central exchange module is mounted in a process zone of an instrument room and constructively it is a lockable metal cabinet with thermoregulation; its protection degree – IP54.

All the equipment components of the central exchange module have light indication of general and emergency operating conditions. Also in the central exchange cabinet power supply system with standby rectifier and batteries is located.

RESULTS

At the moment the system represents a distributed structure of central exchange equipment and periphery subscriber devices. It performs advanced functions apart from the standard ones.

The peculiarity of the project was providing additional test equipment for Transneft pipeline commissioning station that allowed TANECO to launch the first facilities of the plant in time. Afterward the system was expanded to cover all technological and auxiliary areas.

1. The installation of the reliable PA system has reduced number of accidents that results the company image and financially.

2. Due to the flexible and thorough system TANECO increased the productivity of the Complex and provided an extra output.